Views: 0 Author: Site Editor Publish Time: 2024-11-06 Origin: Site

Fiberglass reinforced plastic (FRP) profiles are structural components manufactured from a composite material consisting of high-strength glass fibers embedded in a polymer resin matrix. This combination results in a lightweight yet exceptionally durable material that offers superior performance compared to traditional materials like steel, aluminum, or wood.Unlike metals, FRP profiles do not require anti-corrosion coatings and have a longer service life with minimal upkeep. Their non-conductive nature also enhances safety in electrical applications.With continuous advancements in composite technology, FRP profiles are increasingly becoming the material of choice for sustainable and high-performance engineering solutions worldwide.

FRP profiles possess a range of advantageous properties, including:

Durability

Engineered to endure harsh sunlight and temperature swings without degradation

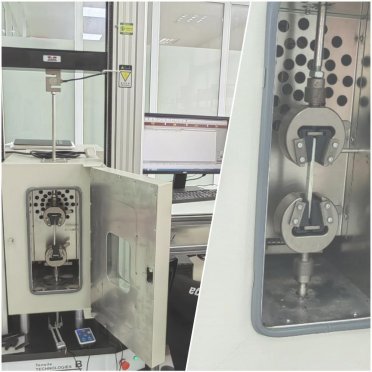

High Strength-to-Weight Ratio

5 times the strength and stiffness of aluminum profilest

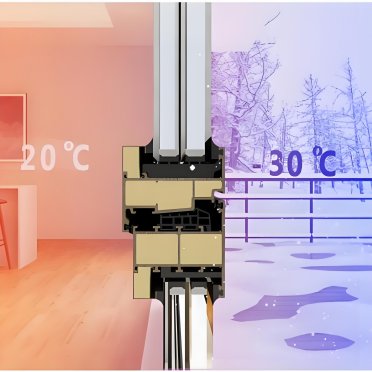

Thermal Insulation

Has great thermal break performance

Corrosion Resistance

Immune to rust and chemical degradation, ideal for harsh environments

Due to its exceptional properties, FRP profiles are extensively utilized in:

Construction: Used in facades, roofing, window frames, and reinforcement structures due to their durability and low maintenance.

Marine & Shipbuilding: Ideal for decks, hulls, and offshore platforms because of their resistance to saltwater corrosion.

Infrastructure: Commonly applied in bridges, tunnels, and highway barriers where long-term resilience is critical.

Petrochemical Industry: Suitable for pipelines, walkways, and chemical storage tanks exposed to corrosive substances.

Transportation: Lightweight properties benefit automotive and aerospace components for fuel efficiency and performance.